Nanotechnology, the science of manipulating and utilizing materials at the nanoscale, has been making significant strides in various industries, including aviation. The integration of nanotechnology in the aviation sector has led to the development of lightweight materials, enhanced fuel efficiency, and improved performance, all of which contribute to a more sustainable and efficient means of air travel. In this article, we will explore the role of nanotechnology in aviation, focusing on its impact on lightweight materials and enhanced performance.

Lightweight Materials

One of the primary goals in the aviation industry is to reduce the weight of aircraft, as lighter planes consume less fuel and produce fewer emissions. Nanotechnology has played a crucial role in achieving this goal by enabling the development of advanced lightweight materials with improved strength and durability. Some of these materials include:

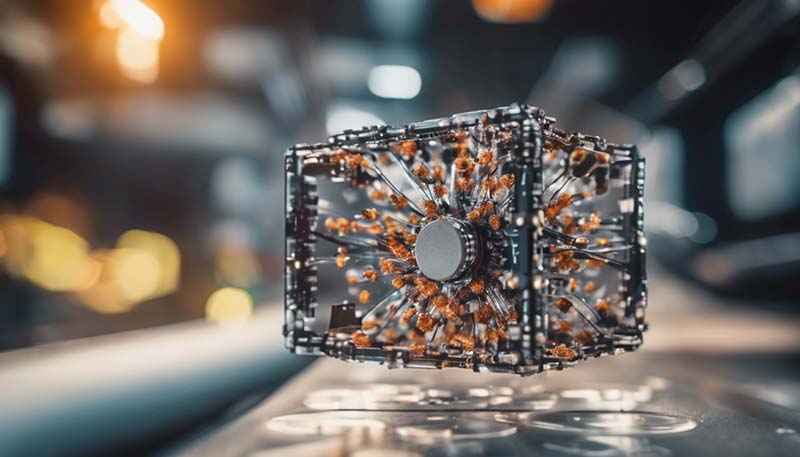

Carbon Nanotubes (CNTs)

Carbon nanotubes are cylindrical nanostructures made of carbon atoms, which exhibit exceptional mechanical, electrical, and thermal properties. These nanotubes have a high strength-to-weight ratio, making them ideal for reinforcing composite materials used in aircraft construction. By incorporating CNTs into composite materials, manufacturers can create lightweight structures with increased strength and stiffness, ultimately leading to reduced weight and improved fuel efficiency.

Advertisement

Graphene

Graphene is a two-dimensional material composed of a single layer of carbon atoms arranged in a hexagonal lattice. It is known for its exceptional strength, lightweight nature, and high electrical and thermal conductivity. Graphene has the potential to revolutionize the aviation industry by offering a lightweight alternative to traditional materials such as aluminum and steel. By incorporating graphene into aircraft structures, manufacturers can significantly reduce the overall weight of the plane, leading to improved fuel efficiency and reduced emissions.

Nanostructured Metals

Nanotechnology has enabled the development of nanostructured metals, which are materials with grains at the nanoscale level. These materials exhibit superior mechanical properties, such as increased strength and ductility, compared to their bulk counterparts. By using nanostructured metals in aircraft components, manufacturers can create lighter and stronger parts, contributing to the overall weight reduction of the aircraft.

Enhanced Performance

In addition to lightweight materials, nanotechnology has also contributed to the enhanced performance of aircraft through the development of advanced coatings, self-healing materials, and improved aerodynamics. Some examples include:

Self-Healing Materials

Self-healing materials are designed to repair themselves when damaged, thereby extending the lifespan of the component and reducing maintenance costs. In the aviation industry, self-healing materials can be used to create aircraft skins and coatings that can repair scratches, dents, and other minor damages. By incorporating self-healing materials into aircraft designs, manufacturers can improve the overall performance and reliability of the plane, leading to reduced downtime and increased operational efficiency.

Nanocoatings

Nanocoatings are thin layers of material applied to surfaces to provide protection and enhance performance. In the aviation industry, nanocoatings can be used to improve the durability and resistance of aircraft components, such as engines and airframes, against environmental factors like corrosion, wear, and extreme temperatures. By using advanced nanocoatings, manufacturers can increase the lifespan of aircraft components and reduce maintenance costs, ultimately leading to improved performance and efficiency.

Improved Aerodynamics

Nanotechnology has also enabled the development of advanced aerodynamic designs, which can significantly improve the efficiency of aircraft. By utilizing nanomaterials and nanostructured surfaces, engineers can create aircraft with reduced drag and improved lift, leading to better fuel efficiency and increased range. Furthermore, nanotechnology can be used to develop adaptive surfaces that can change shape in response to environmental conditions, further enhancing the aerodynamic performance of the aircraft.

Conclusion

Nanotechnology has had a significant impact on the aviation industry by enabling the development of lightweight materials and advanced technologies that enhance performance, fuel efficiency, and sustainability. As research and development in nanotechnology continue to progress, we can expect even more innovations and breakthroughs that will further transform the aviation sector. The integration of nanotechnology in aviation is not only essential for improving the efficiency and performance of aircraft but also crucial for addressing the environmental challenges associated with air travel. With ongoing advancements in nanotechnology, the future of aviation looks promising, with lighter, more efficient, and more sustainable aircraft designs on the horizon.